- Water Systems

-

- Residential RO Systems

- Compact Reverse Osmosis System

- Under Counter Reverse Osmosis System

- Industrial RO Systems

- Seawater Reverse Osmosis Systems

- Brackish Water Reverse Osmosis Systems

- Industrial Water Filtration

- Industrial Water Filtration Systems

- Drinking Water Processing Systems

- Drinking Water Filtration Systems

- Drinking Water Ozone Systems

- Drinking Water Bottling Machines

- Medical Water Applications

- Healthcare Water Purification

-

- AdBlue Production Facility

- Liquid Fertilization System

- About

- Contact

TURN-KEY DEF PRODUCTION PLANT

Euro 5 and 6 emissions standards

Profitable Production

Mixing urea with water, causes a drop in temperature due to its endothermic reaction. Traditional systems require a hefty 75 kW of heating energy to dissolve urea, whereas our system accomplishes the same with only 15 kW. This results in a lower unit cost and increased profitability.

Fast Production

Each batch in our production takes just about 20 minutes, signifying an efficient and energy-saving process for rapid production. In contrast, conventional systems necessitate a minimum of 2 hours for heating and mixing.

Smart Production

Our automated system precisely controls and mixes urea and water without manual intervention. It continuously monitors and adjusts the percentage of each component in real-time. This dynamic process ensures no wasted batches, saving both time and energy efficiently.

Minimum Manpower

A single staff member is sufficient for our production process. Their responsibilities include loading a large bag of urea into the urea hopper, and then they have three hours to monitor the system via the display. After this period, the staff member conducts a quality control check, completing their duties.

Certification

VDA Certificate

ISO 9001

ISO 13485

ISO 14001

Duty Free

We supply the A.TR file. It means that you will not pay Tax on your border.

OTHER STRENGTS

We provide a variety of high-tech solutions with our diverse product portfolio.

FULL AUTOMATED DEF Production

Transfers urea from the hopper

Calculates the water amount is needed

Transfers water from UPW System

Analyzes the mixture continues mixing

Transfers AdBlue to the stock tanks

No wastage/loss in production batches

Saves time, energy, and urea loss

Equipped with accurate sensors

Counting or weighing the Urea sacks in our Production Systems is unnecessary.

The sensors automatically transfer Urea to the Mixer as needed.

VDA Certificate Cosultancy

After starting production, full consultancy for getting VDA certificate in one of our service

User Friendly UX/UI Design

Online Access and Intervention

OUR MODELS

ADB 1800

CAPACITY: 2 m3/h

ELECTRIC: 380 V – 10 kW

NEEDED AREA: 300 m2

ADB 4800

CAPACITY: 6 m3/h

ELECTRIC: 380 V – 12 kW

NEEDED AREA: 350 m2

ADB 7200

CAPACITY: 9 m3/h

ELECTRIC: 380 V – 15 kW

NEEDED AREA: 400 m2

ADB 9600

CAPACITY: 12 m3/h

ELECTRIC: 380 V – 15 kW

NEEDED AREA: 450 m2

TRIPLE PASS RO SIDE

ADJUSTABLE WITH ALL WATER QUALITIES

| Characteristics | Unit | Drinking Water (ISO: 10500) | Deionized Water (ISO 22241) |

|---|---|---|---|

| Aluminum | mg/l Max | 0.03 | 0.5 |

| Calcium | mg/l Max | 75 | 0.5 |

| Iron | mg/l Max | 0.3 | 0.5 |

| Magnesium | mg/l Max | 30 | 0.5 |

| Conductivity | μS/m | 5,000-50,000 | 5.5 |

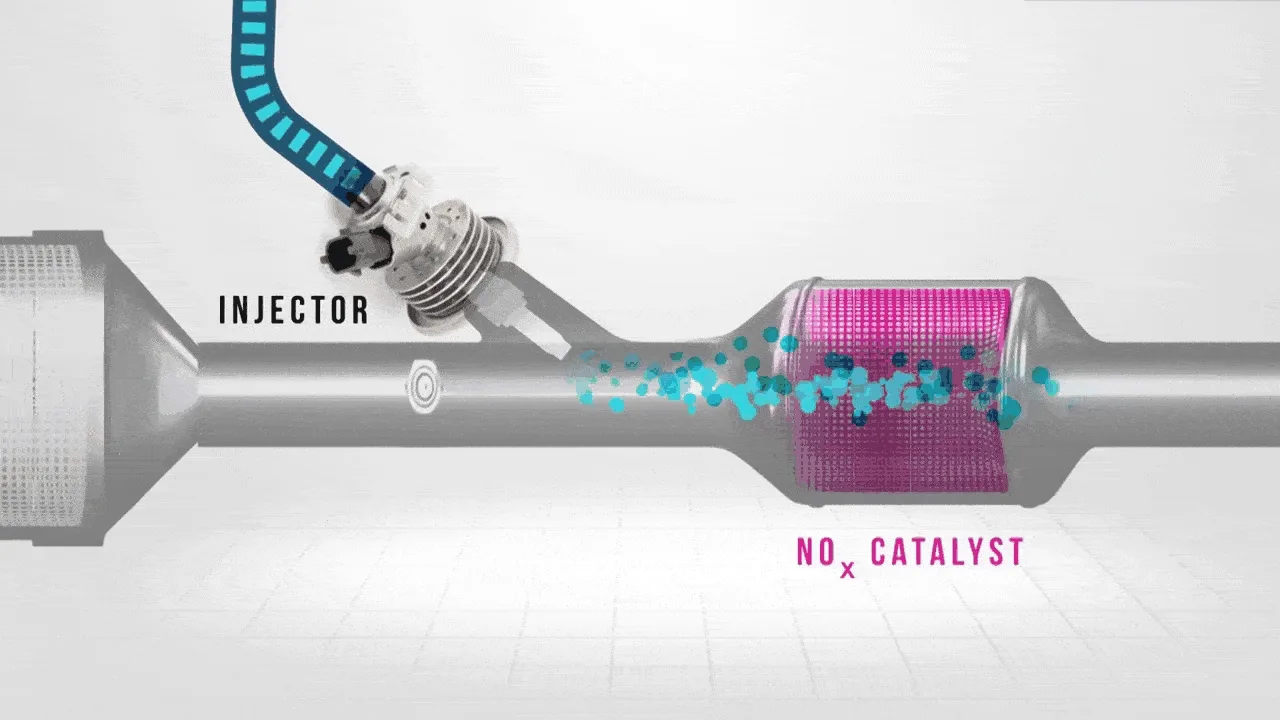

How does AdBlue® work in the SCR system?

The SCR system injects AdBlue® directly into the exhaust stream. When it enters the catalytic converter, it reacts with nitrous oxides from the combusted diesel – producing non-hazardous, naturally occurring nitrogen and water. Due to its outstanding purity, AdBlue® by Our System neither damages the SCR system nor reduces3 its lifespan.

THE EFFECTS OF WATER AND UREA QUALITY ON THE SCR SYSTEM

DEF by Our

System

- Reduces maintenance costs

- Extends SCR system lifespan

- Ensures SCR system efficiency

- Improves fuel economy

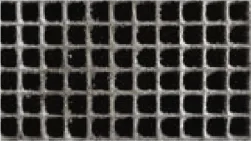

SCR system after 40,000 km

using DEF such as AdBlue® by Our System

DEF by traditional systems

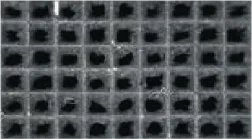

- Reduced SCR system lifespan

- Increased emission of pollutants

- Clogged catalytic converter

- Clogged exhaust and injector

SCR system after 40,000 km

using low-quality traditional systems

| AdBlue® Specifications During VDA Standards | ||

|---|---|---|

| APPEARANCE | CLEAR LIQUID | DN 8-53 |

| UREA CONTENT | 32.5 ± 0.7 | ISO 22241-2 |

| ALKALINITY AS NH3 | 0.2 % MAX | ISO 22241-2 |

| REFRACTIVE INDEX AT 20°C | 1.3814 – 1.3843 | ISO 22241-2 |

| BIURET | 0.3 WT% MAX | ISO 22241-2 |

| ALDEHYDES | 5.0 MG/KG MAX | ISO 22241-2 |

| INSOLUBLE MATTER | 20 MG/KG MAX | ISO 22241-2 |

| PHOSPHATE (PO4) | 0.5 MG/KG MAX | ISO 22241-2 |

| CALCIUM | 0.5 MG/KG MAX | ISO 22241-2 |

| IRON | 0.5 MG/KG MAX | ISO 22241-2 |

| COPPER | 0.2 MG/KG MAX | ISO 22241-2 |

| ZINC | 0.2 MG/KG MAX | ISO 22241-2 |

| CHROMIUM | 0.2 MG/KG MAX | ISO 22241-2 |

| NICKEL | 0.2 MG/KG MAX | ISO 22241-2 |

| SODIUM | 0.5 MG/KG MAX | ISO 22241-2 |

| ALUMINIUM | 0.5 MG/KG MAX | ISO 22241-2 |

| MAGNESIUM | 0.5 MG/KG MAX | ISO 22241-2 |

| POTASSIUM | 0.5 MG/KG MAX | ISO 22241-2 |

| IR | YES | IDENTICAL TO REFERENCES |